Have you ever wondered what temperature does silicone melts at? Perhaps you’re baking with silicone molds, sealing gaps with silicone caulk, or using silicone gaskets in a project, and you’re concerned they’ll melt under high heat. It’s a common question: nobody wants their tools or materials to fail when things get hot. The truth is, silicone behaves very differently from most materials, and that’s why so many people are curious about it.

In this blog, we’ll break down exactly what temperature does silicone melts and why the answer isn’t as simple as it seems. You’ll learn how silicone actually reacts to heat, the temperatures different types of silicone can handle, and what happens when it reaches its limits. By the end, you’ll know whether your silicone product is safe to use in high-heat situations and how to choose the right type for your needs.

How Hot Can Silicone Get Before It Melts?

Unlike most plastics, silicone rubber doesn’t melt when heated. Instead, it stays solid and stable across an impressively wide temperature range from as low as –50 °C to –75 °C all the way up to 200–300 °C depending on the grade. This makes it an ideal choice for kitchenware, aerospace components, automotive gaskets, and medical devices where both heat resistance and flexibility matter.

At extreme heat, though, silicone behaves differently. Once it reaches around 200 °C, its mechanical properties gradually change; it becomes harder and more brittle. Beyond 300 °C, the process accelerates. Autoignition is the point at which silicone combusts, typically happening near 450 °C, but not because it “melts.” Rather, its siloxane chains begin to break down chemically, releasing gases and leaving behind a white silica residue that actually helps insulate and slow further combustion.

Silicone Rubber Melting Point

So what is the actual “melting point” of silicone rubber? Technically, there isn’t one. Silicone is a thermoset polymer, not a thermoplastic. That means once it’s been cured and cross-linked, it won’t melt back into a liquid. Instead, it softens slightly at high heat, then degrades or burns rather than melting like butter or plastic. This unique property comes from its silicon-oxygen backbone, which forms strong covalent bonds and gives silicone its extraordinary thermal stability.

This stability explains why silicone is used everywhere from flexible oven-safe bakeware to industrial seals. High-temperature silicone grades can handle intermittent exposure up to 300 °C (572 °F), while heat-stabilized grades can withstand about 260 °C continuously. For everyday products like kitchen utensils, medical tubing, or baby bottle nipples, you’re well within the safe zone. Even boiling water (100 °C / 212 °F) is no problem at all silicone doesn’t melt in boiling water.

Read More Article: What to Wear to a Chiropractor:

Subscribe to Our Newsletter

Want more expert tips and insights about silicone materials, manufacturing, and performance? Subscribe to our newsletter to get updates, guides, and behind-the-scenes looks at how we create high-quality silicone products for industries worldwide.

Navigation

- Home

- Products

- Resources

- Contact

UK Head Office

Viking Extrusions Ltd.

[Address details here]

Company Information

- About Us

- Careers

- Quality Certifications

Privacy Preference Center

We respect your privacy. This section explains how we handle your data when you interact with our website, newsletter, or products.

Manage Consent Preferences

Adjust your cookie and data-sharing settings at any time.

Strictly Necessary Cookies

These ensure our website functions properly.

Performance Cookies

These help us improve website performance.

Targeting Cookies

Used for marketing and advertising preferences.

What Temperatures Can Different Grades of Silicone Withstand?

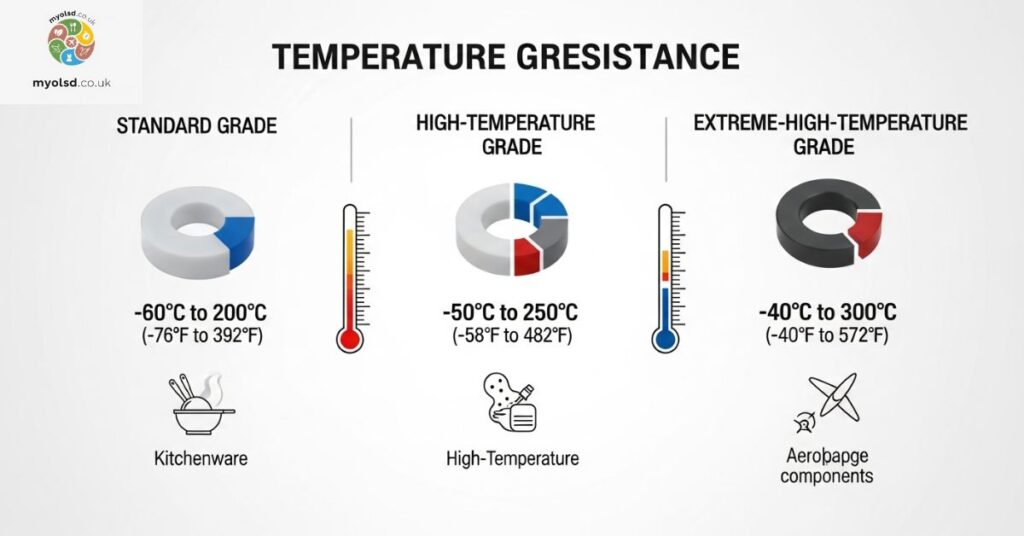

Different grades of silicone rubber are designed for different conditions:

- General-purpose silicone: Typically –50 °C to –75 °C up to 200–250 °C

- Heat-stabilized silicone: Continuous operation up to 260 °C

- High-temperature silicone: Intermittent exposure up to 300 °C (572 °F)

- Flame-retardant grades: Intermittent exposure up to ~220 °C with self-extinguishing properties

These variations come from additives, fillers, and curing methods like addition curing or peroxide curing. For example, high-temperature vulcanizing (HTV) silicone, room-temperature vulcanizing (RTV) silicone, liquid silicone rubber (LSR), and fluorosilicone rubber (FVMQ) all have slightly different performance profiles.

Another factor is exposure duration. A gasket might survive 300 °C for a few minutes, but continuous exposure would shorten its life. Moisture, oxygen, and chemical environment also influence how silicone behaves at high heat.

Silicone’s Behavior During Combustion

When silicone finally reaches autoignition (around 450 °C / 842 °F), it doesn’t melt into a puddle. Instead, it smokes, cracks, and expands before combusting. As it burns, it releases carbon dioxide and water vapor while leaving behind a white powder of silicon dioxide. This powder acts as an insulating layer, slowing further combustion one more reason silicone is considered flame-resistant.

This unique combustion behavior makes silicone a trusted material in industries like aerospace, automotive, and medical devices, where reliability under extreme conditions is essential.

What Is Silicone Made Of?

To understand why silicone doesn’t have a melting point, it helps to know its chemistry. Silicone is made by combining silicon (a natural element found in quartz sand) with oxygen, carbon, and hydrogen to create long siloxane chains. Through a crosslinking process, these chains form a permanent network that resists melting.

Manufacturing involves heating quartz sand to isolate silicon, reacting it with methyl chloride, then distilling it into polydimethylsiloxane (PDMS). This PDMS is then polymerized into solid silicone rubber. Different curing mechanisms, like addition curing or peroxide curing, plus fillers and stabilizers, produce the variety of silicone grades we see on the market.

Other Advantages of Silicone Rubber

Silicone isn’t just heat-resistant. It also:

- Has low thermal conductivity, making it a good insulator.

- It is an elastomer; it stretches and snaps back to shape.

- Repels water, which is great for watertight seals and gaskets.

- It is non-toxic and biocompatible, perfect for medical-grade and food-grade uses.

- Shows excellent chemical resistance and UV/weathering stability, making it durable outdoors.

These properties explain why silicone appears in kitchenware, automotive parts, aerospace seals, baby products, and industrial applications. Its unique blend of flexibility, thermal stability, and chemical resistance sets it apart from other rubbers like polyurethane, nitrile, or polyacrylate.

Conclusion

So, what temperature does silicone melt? In short, it doesn’t, at least not in the way most people think. Silicone rubber doesn’t have a melting point; it stays solid until it degrades or combusts at extremely high temperatures around 450 °C. Between 50 °C and 300 °C, it remains stable and reliable, especially if you choose the right grade for your application.

Whether you’re baking cookies, sealing an engine, or designing medical devices, silicone’s ability to withstand heat makes it one of the most versatile materials around. With the right grade and proper use, you can count on silicone to perform without melting, warping, or losing integrity.

FAQS

What temperature does silicone melt at in Celsius?

Silicone doesn’t have a true melting point; it stays solid until it starts degrading above about 300 °C and combusts near 450 °C.

Is silicone ok for high heat?

Yes, most silicone grades handle continuous high heat up to 200 to 300 °C without melting.

Does 100% silicone melt?

No, 100% silicone doesn’t melt; it only hardens and degrades at extreme temperatures.

Does silicone melt in hot water?

No, silicone won’t melt in boiling water (100 °C); it stays completely stable.

Will boiling water ruin silicone?

No, boiling water (100 °C) won’t ruin silicone; it stays stable and unaffected at that temperature.

What are the disadvantages of silicone?

Silicone can be more expensive, less tear-resistant, harder to bond or glue, and may degrade faster when exposed to oils, fuels, or very high heat over time.